Blog

Self-Lubricating Bearings for OEM Automation: Supplier Standards That Matter

February 19, 2026

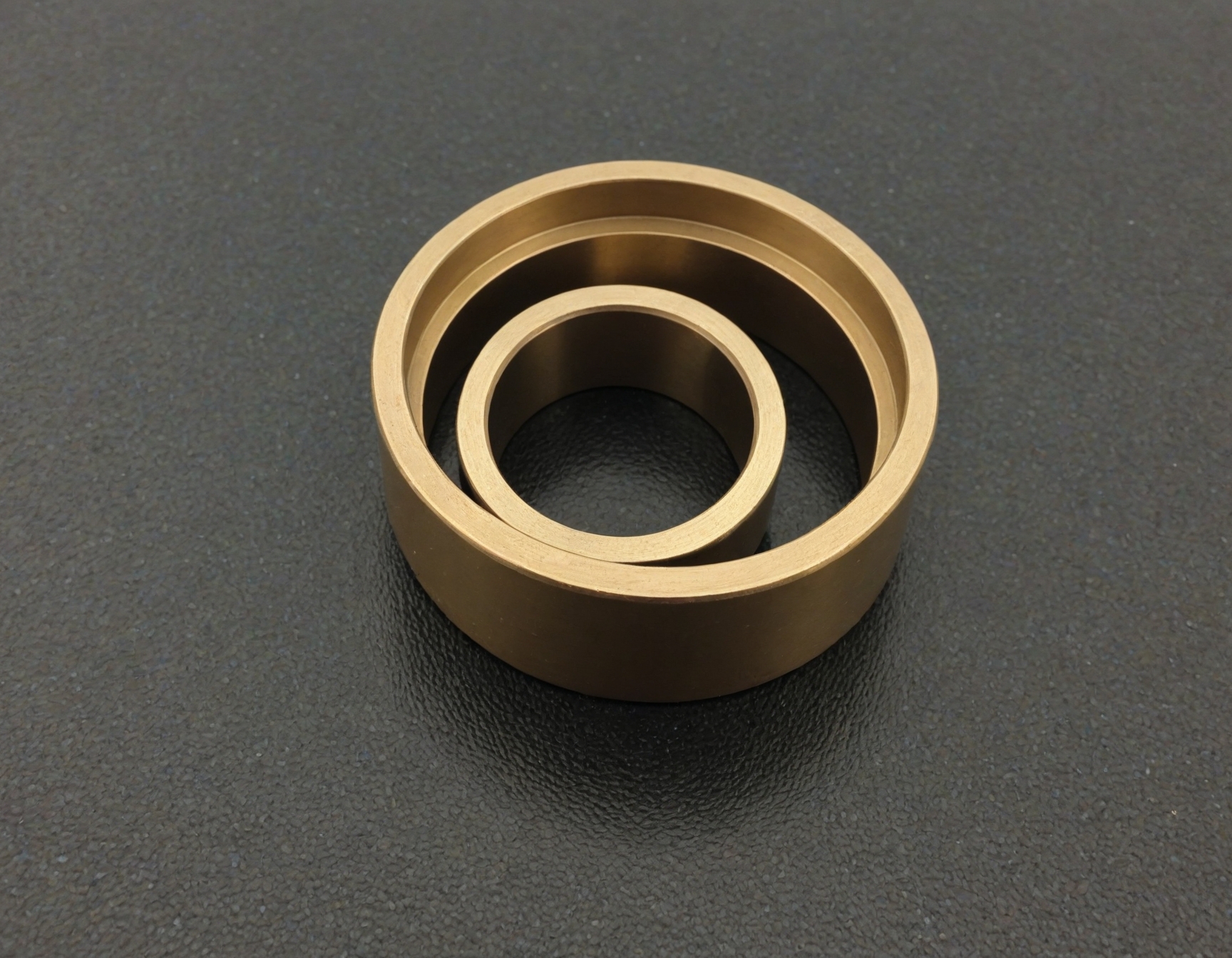

Support OEM automation projects in Melbourne with PM Distributors, a self-lubricating bearings supplier focused on reliable supply and OEM needs.

Automation systems demand reliability, repeatability, and minimal maintenance to sustain consistent OEM performance. Self-lubricating bearings help reduce downtime, but only when sourced from a capable self-lubricating bearings supplier that meets strict quality and supply standards. For OEM automation environments, procurement decisions are driven by supplier compliance, consistency, and long-term availability rather than bearing theory alone.

Why OEM Automation Places Higher Demands on Bearing Suppliers

• Continuous operation environments: Automated systems often run for extended periods, requiring bearings that maintain stable performance under constant motion and load.

• Tight tolerances and consistency across production runs: Even minor dimensional variation can disrupt automated processes, making batch-to-batch consistency essential for OEM equipment.

• Downtime costs in automated systems: Unplanned bearing failures can stop entire production lines, resulting in significant financial and operational losses.

Performance and Consistency Requirements for OEM Supply

Beyond meeting baseline performance expectations, OEM bearing supply also depends on strict manufacturing consistency to ensure every unit delivers the same reliable fit and function in high-precision applications.

• Dimensional Accuracy and Repeatability: Consistent dimensional accuracy ensures bearings fit correctly across batches without requiring rework or design modification. In automated systems, poor repeatability can cause misalignment, vibration, and accelerated component wear.

• Material Performance Under Continuous Operation: Bearings used in automation must handle ongoing loads, operating speeds, and temperature exposure without performance loss. Material suitability is critical in dry or maintenance-restricted environments where re-lubrication is limited or impractical.

• Supply Capabilities OEMs Expect as Standard: OEM automation projects depend on suppliers who can support production continuity and long-term equipment builds. Supply capability is critical in preventing disruptions that can delay manufacturing schedules or compromise system design.

• Bulk and Repeat Order Availability: OEMs require suppliers that can support bulk volumes and repeat orders without variation in specification or quality. Reliable availability helps avoid costly redesigns or component substitutions caused by unexpected supply changes.

• Stock Holding and Lead Time Reliability: Consistent stock holding reduces reliance on offshore supply chains that can introduce unpredictable delays. Reliable lead times allow OEMs to plan automation projects accurately and meet delivery commitments with confidence.

Automation Applications Where Self-Lubricating Bearings Are Critical

• Conveying systems: Support continuous movement of materials while reducing friction and wear in high-cycle environments.

• Robotics and actuators: Enable precise, repeatable motion in joints and linkages where lubrication access is limited.

• Packaging, sorting, and assembly machinery: Maintain smooth operation across fast-paced, repetitive processes with minimal downtime.

• Linear motion and guide systems: Ensure stable, low-friction movement in applications requiring accurate positioning and alignment.

Supplier Support That Adds Value Beyond the Bearing

Effective supplier support extends beyond component supply and plays a critical role in OEM automation outcomes. Reliable guidance helps ensure bearings are correctly specified for application, load, and operating conditions.

OEMs also benefit from suppliers that can respond quickly to specification changes without compromising compliance or availability. Clear documentation and product traceability further support quality assurance, regulatory requirements, and long-term equipment support.

Supporting OEM Automation Projects with PM Distributors

PM Distributors brings established industrial supply experience to OEM automation projects, supporting manufacturers that require consistent quality and dependable sourcing from a self-lubricating bearings supplier. Our range of self-lubricating bearing solutions helps OEMs maintain specification alignment across automated systems and production runs.

OEM and automation clients can explore our self-lubricating bearing range online and contact us for practical guidance.

Reliable Automation with the Right Self-Lubricating Bearings Supplier

OEM automation success depends on reliable supply, consistent support, and long-term supplier alignment rather than component selection alone. At PM Distributors, self-lubricating bearings achieve dependable performance when sourced through a trusted self-lubricating bearings supplier with proven supply continuity and technical support.

Related Blog Article: Sintered Self-Lubricating Bearings – Enhancing Agricultural Machinery Efficiency in Australia

Optimized by: Netwizard SEO