Blog

Metric Flanges: Sintered for Durability and Efficiency

May 28, 2024

Explore the durability and efficiency of sintered metric flanges, optimising engineering system performance. Call PM Distributors now to learn more!

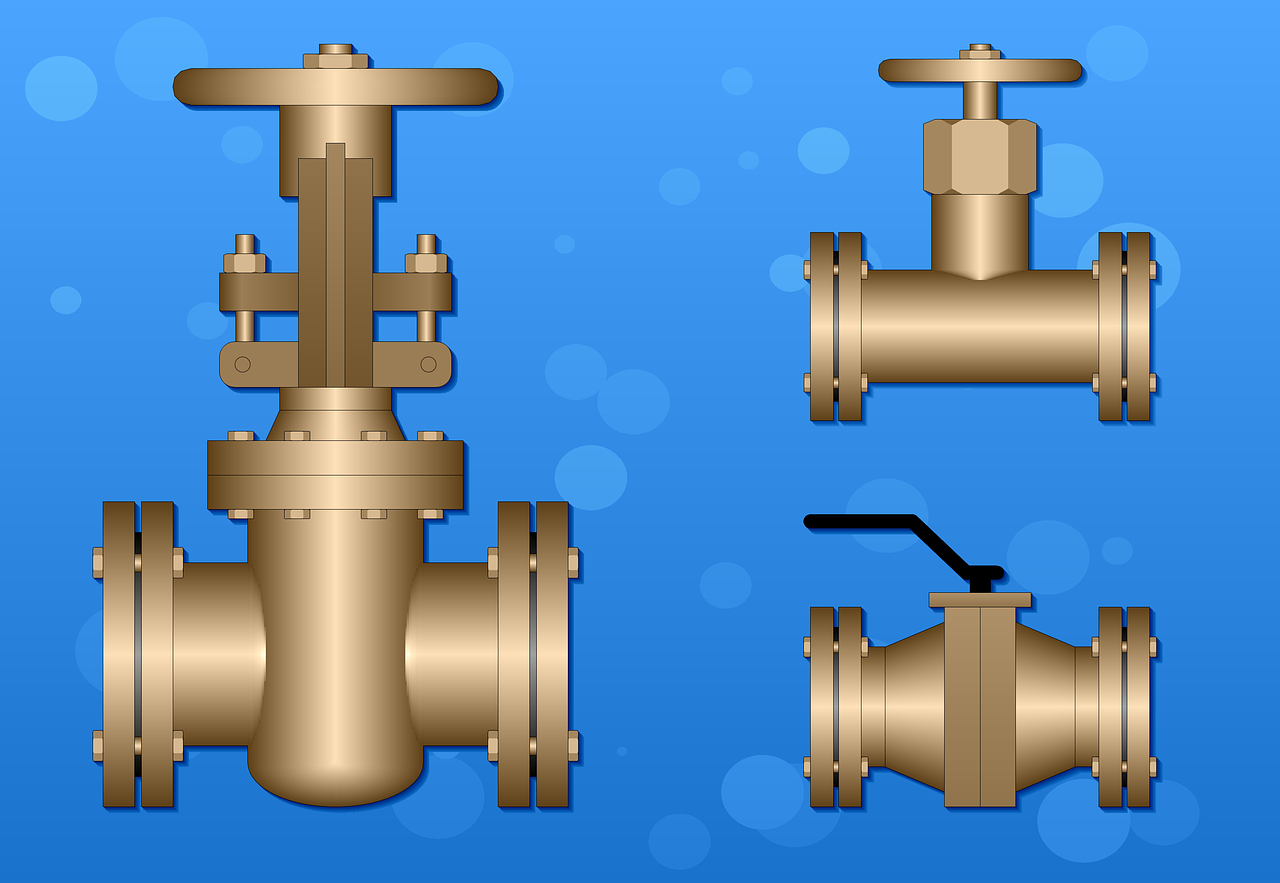

Flanges play a crucial role in connecting and sealing piping systems in engineering and industrial applications. These essential components ensure reliable and secure connections, facilitating the smooth flow of fluids or gases. Among the various flanges available, metric flanges stand out for their precision and compatibility with international standards.

What Are Flanges and Their Role in Engineering Systems?

Flanges are sturdy components designed to connect pipes, valves, and other equipment securely and leak-proof. They are typically made of durable materials such as steel, stainless steel, or other alloys, ensuring long-lasting performance in demanding industrial environments. Flanges are essential for maintaining the integrity of piping systems, preventing leaks, and facilitating easy assembly and disassembly when necessary.

Common Metric Flanges

The metric system of flanges is widely adopted globally, ensuring compatibility and standardisation across different industries and applications. Here are five common metric flanges:

• Weld Neck Flanges – Weld neck flanges feature a cylindrical collar (or hub) that extends from the flange face, allowing for welding directly onto the pipe or vessel. This design provides exceptional strength and rigidity, making it suitable for high-pressure and high-temperature applications.

• Slip-On Flanges – Slip-on flanges are designed to be slipped over the pipe end and then welded in place. They offer a cost-effective solution for low to moderate-pressure applications and are commonly used in various industries, including oil and gas, chemical processing, and water treatment.

• Blind Flanges – Blind flanges, also known as blanking flanges, are used to seal off the ends of pipes or vessels. They are solid and do not have a bore, providing a secure closure for maintenance, testing, or temporary shutdowns. Blind flanges are available in various sizes and pressure ratings to meet specific application requirements.

• Lap Joint Flanges – Lap joint flanges feature a raised face that overlaps with a matching groove on the mating flange. This design creates a metal-to-metal contact, ensuring a tight seal and strength. Lap joint flanges are commonly used in low-pressure applications and are popular in the food and beverage industry due to their easy disassembly and cleaning.

• Threaded Flanges – Threaded flanges, as the name suggests, have internal or external threads that allow for connection to threaded pipes or fittings. These flanges offer a convenient and secure method for joining piping components, particularly in small-diameter applications. They are widely used in various industries, including plumbing, instrumentation, and chemical processing.

Metric flanges, crafted through advanced sintering processes, offer exceptional durability and efficiency in various engineering applications. These flanges ensure compatibility and seamless integration into industrial systems by adhering to international standards. Whether you require weld neck, slip-on, blind, lap joint, or threaded flanges, PM Distributors is a trusted manufacturer and supplier of sintered components, powdered metal, and bearings in Melbourne. With our commitment to quality and expertise, they can provide reliable solutions tailored to your specific needs.

Explore our extensive range of products and unlock the potential for enhanced performance, reliability, and efficiency in your engineering projects. Call our knowledgeable team today to discuss your requirements and experience the excellence of sintered components.

Optimized by: Netwizard SEO