Blog

Benefits of Sintered Components in Customised Bearing Requirements

August 21, 2017

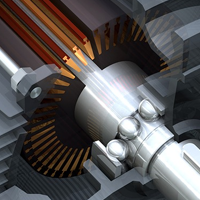

When a shrewd bearing manufacturer takes advantage of sintered components, new product lines gain tailor-designed features and functions. To put it another way, customised bearing requirements are readily expedited when that manufacturer embraces sintering technology. First of all, even the most professionally equipped machine shop uses a subtractive process to fabricate its mechanical bearings. Sintered bearings are made from a powder compaction and heating technique, so there’s no waste.

Material Waste Reduction

While this custom-built feature may not seem like a benefit, one that’s felt by the customer, there are advantages to this naturally eco-friendly process. Costs are driven down because there’s no subtractive waste left over. If there are any particulate detritus or bearing lubricant traces left behind, the materials are recycled.

Satisfying Customised Bearing Requirements

Next on the agenda, a prized customer is seeking a specially configured bearing. Sintered components are imbued with a material-trapped lubricant. If the loading profile of that customer’s equipment is in flux, the manufacturing line can alter the lubricant ratio with a few adjustments to a control station. The heat, pressure, even the lubricant quantity and type, are all governable at the fabrication stage. Better yet, the newly tailored parts will all leave the production line with those altered performance characteristics fully intact, for the sintering process is designed to repeatably imbue every batch-fed bush and bearing with absolutely identical load handling specs.

Assorted Musings on Sintered Components

The addition of a flange or a collar, the widening of the diameter of the bearing or the addition of a special keying mechanism, sintered components reliably adapt during the fabrication stage so that they immediately satisfy those needs. Traditional bearings, assembled from many components and exposed to exotic heat treatment stages, don’t necessarily emulate that repeatability factor, not when the heat or machining adds cold work stress and surface hardened variability to the mix. Built to bend to the will of pressure-based machinery and a tight-tolerance heat cycle, the high-strength, high-precision sintered parts obey those direct application mechanism without incurring work stress. Likewise, a customised bearing won’t lose its key friction-handling parameters when the compacted metal particles assume more volume or a different operational profile.

Based on particle compaction technology and heat-locked manufacturing science, sintered components don’t suffer from the same issues that trouble subtraction fabrication processes. Indeed, customised bearings adapt to this production equipment with ease, without the need for heat treatment alterations or a subsequent change in an in-situ lubricating agent. Essentially, then, these tailored alterations take place at the factory, at a site where the custom-designed alterations can proliferate in batches so that the changes to the bearing are repeatedly and reliably incorporated.

Optimized by: Netwizard SEO