Blog

Sintered Bronze Sleeve Bearings: Prolonging Equipment Lifespan

July 29, 2024

Discover how sintered bronze sleeve bearings from PM Distributors can prolong the lifespan of your equipment. Learn about these versatile bearings.

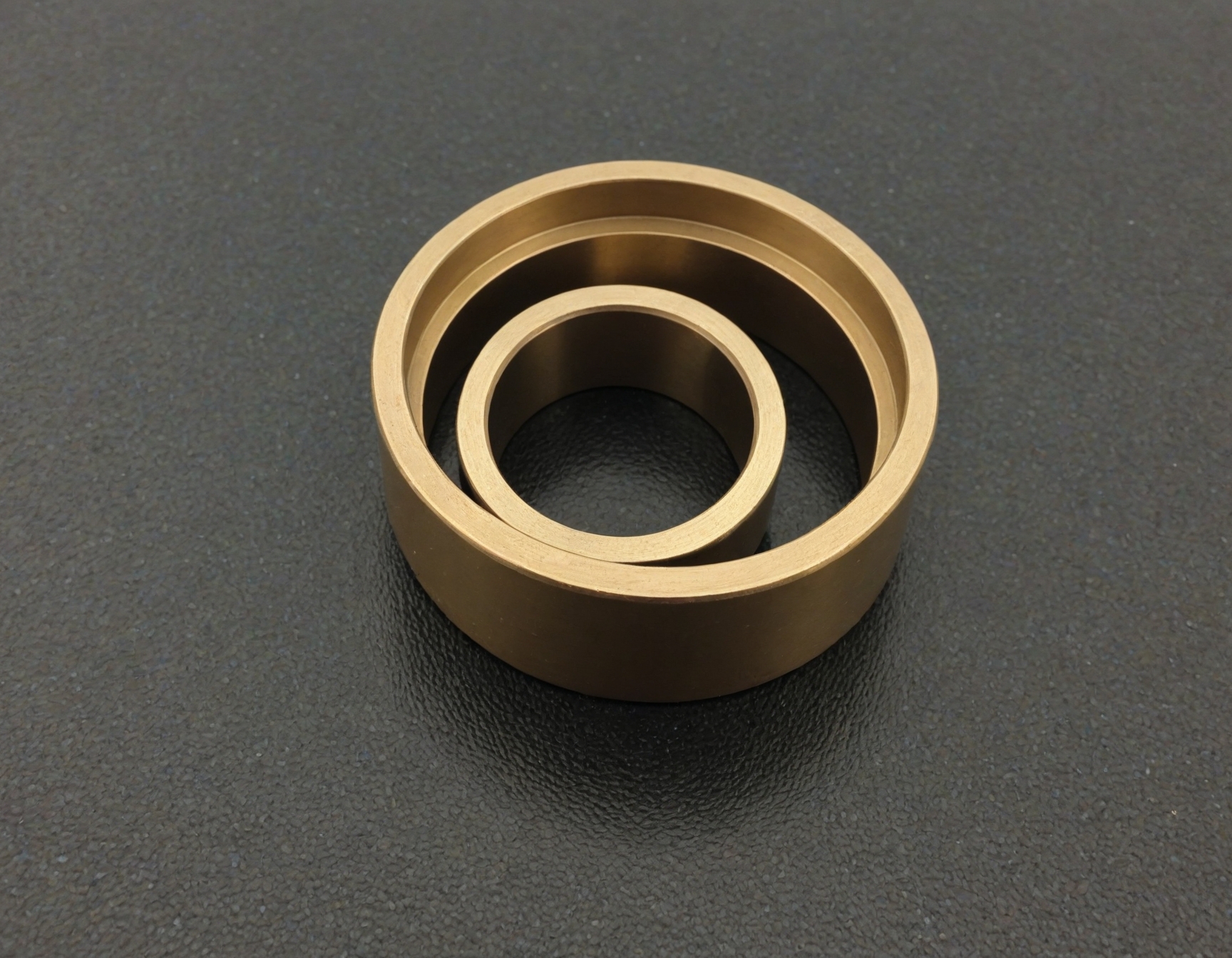

Sintered Bronze Sleeve Bearings are essential components in modern machinery, offering exceptional durability and performance. These precision-engineered bearings play a crucial role in extending equipment lifespan by reducing friction and wear between moving parts.

With their porous structure and self-lubricating properties, sintered bronze bearings provide superior load-bearing capacity and smooth operation across a wide range of applications. From automotive engines to industrial machinery, these bearings contribute significantly to improved efficiency and reduced maintenance costs.

What are Sintered Bronze Sleeve Bearings?

Sintered bronze sleeve bearings are cylindrical bearings made from powdered bronze that have been compressed and heated to just below their melting point. This process, known as sintering, creates a porous structure that allows the bearing to hold lubricant within its walls. The result is a self-lubricating bearing that offers excellent performance in a wide range of operating conditions.

Benefits of Sintered Bronze Sleeve Bearings

• Self-Lubrication: The porous structure of the bearing material acts as a reservoir for lubricant, continuously releasing small amounts during operation. This feature reduces the need for frequent maintenance and helps prevent dry-running conditions that can lead to premature wear.

• Wear Resistance: Sintered bronze is known for its excellent wear resistance, especially when compared to other bearing materials. This characteristic helps to extend the lifespan of both the bearing and the equipment it supports, reducing downtime and replacement costs.

• Load Capacity: Despite their relatively simple design, sintered bronze sleeve bearings can handle substantial loads, both radial and axial. This makes them suitable for a wide range of applications, from light-duty equipment to heavy industrial machinery.

• Cost-Effectiveness: The combination of long service life, low maintenance requirements, and relatively low production costs makes sintered bronze sleeve bearings a cost-effective choice for many businesses.

• Versatility: These bearings can operate effectively in various environments, including those with high temperatures, dusty conditions, or exposure to certain chemicals.

How Do Sintered Bronze Bearings Prolong Equipment Lifespan?

Sintered Bronze Sleeve Bearings prolong equipment lifespan in several key ways:

1. Reduced friction: The porous structure of sintered bronze allows these bearings to retain oil, providing continuous lubrication. This significantly reduces friction between moving parts, minimizing wear and extending the life of both the bearing and the equipment it’s used in.

2. Heat dissipation: The bronze material and oil-impregnated structure help dissipate heat effectively, preventing overheating and thermal damage to equipment components.

3. Contamination resistance: The self-lubricating nature of these bearings means they’re less likely to accumulate contaminants, which can cause premature wear in other types of bearings.

4. Shock absorption: Sintered bronze bearings can absorb vibrations and minor shocks, reducing stress on other equipment components.

5. Corrosion resistance: Bronze is naturally resistant to corrosion, helping to protect equipment in harsh environments.

By addressing these factors, sintered bronze sleeve bearings contribute to smoother operation, reduced maintenance needs, and ultimately, a longer operational life for the equipment they’re used in.

At PM Distributors, we understand that selecting the appropriate bearing for your specific application is crucial. Factors to consider when choosing a sintered bronze sleeve bearing include load requirements, operating speed, environmental conditions (temperature, humidity, presence of contaminants), lubrication needs and installation method. Contact us for more information.

Optimized by: Netwizard SEO