Blog

Glacier Bearings for Heavy-Duty Machinery: Engineering Specs OEM Buyers Rely On

February 5, 2026

Reduce machinery wear effectively using glacier bearings available from PM Distributors in Melbourne, engineered to meet strict OEM performance standards.

Reliability is essential for heavy-duty machinery that works in tough conditions, where part failure causes expensive delays. Original Equipment Manufacturers (OEMs) need parts that meet strict engineering rules to guarantee long life and performance. Using high-quality glacier bearings ensures the required strength and accuracy for continuous, heavy-load industrial jobs.

Advanced Material Science in Constructing Glacier Bearings

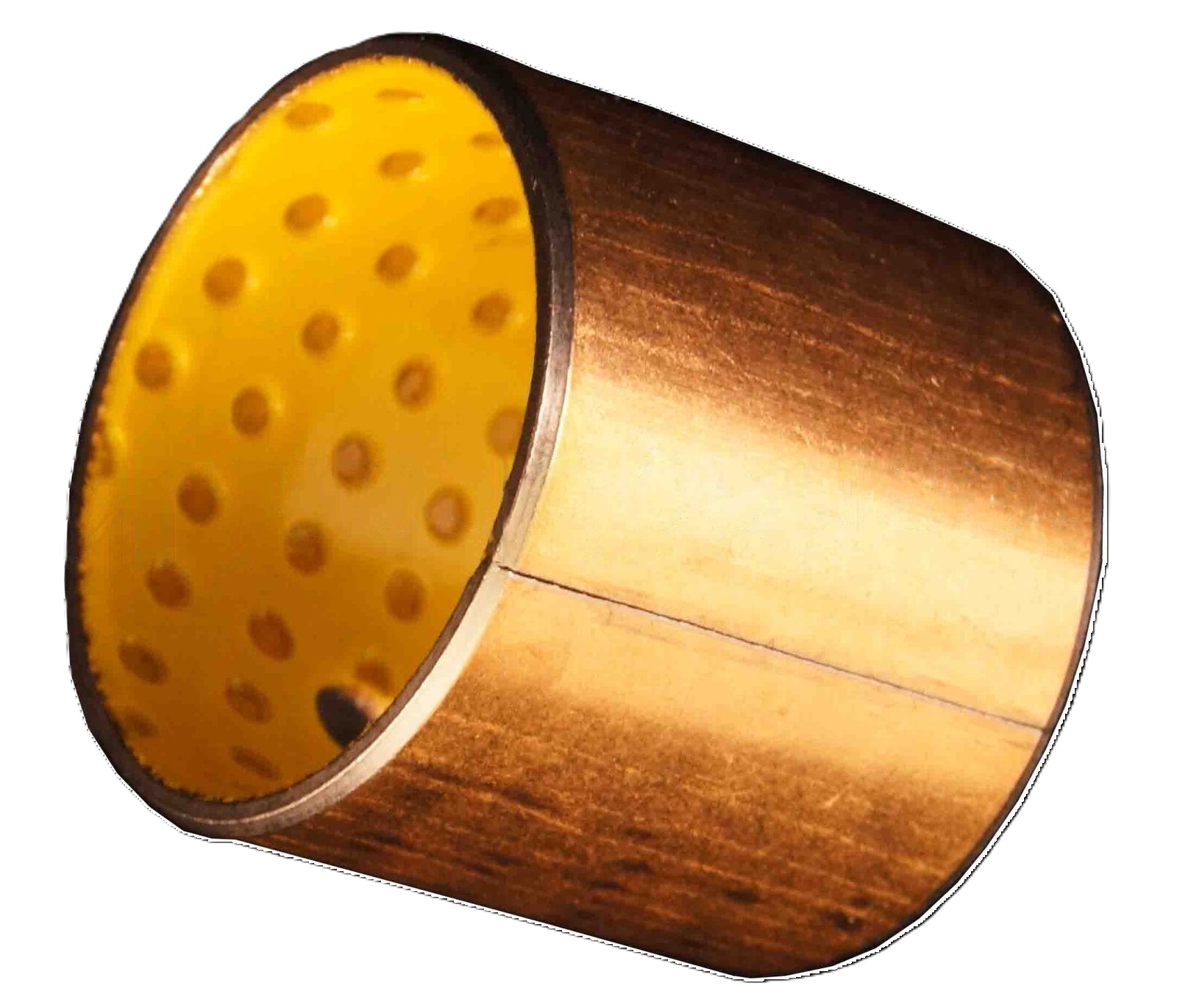

Selecting the appropriate bearing material directly influences the maximum load capacity and operational temperature tolerance of the machinery. Bimetallic constructions utilise a robust steel shell to provide structural integrity. A precisely specified bronze or PTFE lining delivers optimal friction characteristics.

Engineers must rigorously evaluate parameters like fatigue strength and corrosion resistance when specifying bearings for demanding applications. Precision manufacturing ensures the necessary geometric accuracy. This accuracy is critical for maintaining adequate oil film thickness and preventing premature wear, even under dynamic loading conditions.

For further knowledge about the fatigue and construction of multilayer coatings for plain bearings, see the technical thesis on “Fatigue of multilayer coatings for plain bearings”.

Specifying High-Performance Bearing Alloys

OEMs assessing components need to look beyond dimensional requirements and evaluate the inherent properties of the bearing alloys selected. These engineered metal combinations are developed to manage poor lubrication conditions while supporting heavy and repetitive loads. Their structural stability prevents premature failure in machinery exposed to continuous operational stress.

Engineers rely on performance criteria such as load-bearing capacity, friction and wear behaviour, corrosion resistance, thermal conductivity, and fatigue strength. Each characteristic directly influences operational reliability and the lifespan of the bearing surface. These material attributes collectively ensure stable performance in heavy-duty applications.

Performance Metrics for Critical Industrial Applications

A bearing works successfully only if it meets measurable performance standards that directly lead to the machine’s overall efficiency and reliability. These numbers guide the OEM’s decision, making sure the chosen part fits perfectly with the job’s work cycle and maintenance schedule.

Essential engineering specifications:

• Maximum Specific Pressure: This is the highest unit load the bearing can safely take, which is important for sizing parts in hydraulic cylinders and gearboxes.

• Operating Temperature Range: This range defines the environmental limits where the bearing materials keep their strength and best performance characteristics.

• Coefficient of Thermal Expansion: Ensuring this matches the housing material is critical to prevent clearance issues and seizing as the temperature changes.

• Surface Finish and Roughness: A very smooth surface is needed to help with lubrication, and this specification is especially vital in non-metallic glacier bearings that use thin film lubrication.

• Maximum Shaft Speed: The fastest allowed rotation speed depends on the bearing’s design, material, and lubrication, which directly affects its speed and load limits (P-V value).

Securing Operational Efficiency and Longevity

At PM Distributors, we supply engineered bearing solutions that support the high mechanical demands of Australian heavy-duty machinery. Our glacier bearings deliver stable friction control, extended service life, and consistent operation across a wide range of industrial environments. We ensure OEM buyers receive components manufactured to exact tolerances for dependable long-term performance.

Browse our complete bearing range on our website to support your machinery requirements.

For technical guidance or product selection assistance, contact us.

Related Blog Article: We Supply Glacier Bearings: Know About Their Main Applications

Optimized by: Netwizard SEO