Blog

How Powdered Metal Parts Improve Wear Resistance in Industrial Machines

April 23, 2025

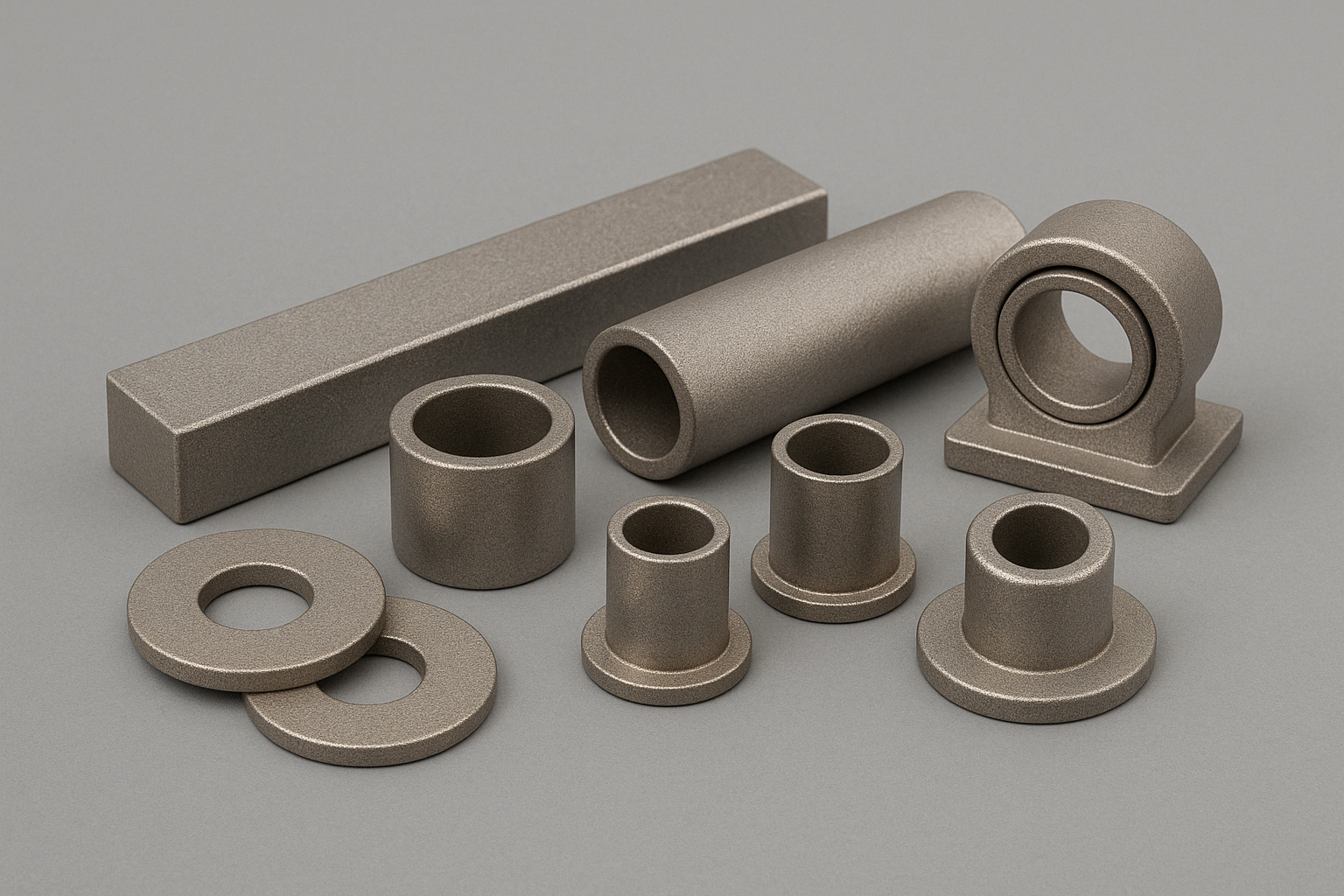

Strengthen industrial equipment with powdered metal parts from PM Distributors, offering unmatched wear resistance and long-term efficiency.

Powdered metal parts enhance wear resistance in industrial machinery, ensuring prolonged operational efficiency. The unique material blend minimises friction, improves wear resistance, and significantly prolongs the lifespan of critical machine components.

Boosting Industrial Machine Durability with Powdered Metal Parts

Powdered metal components significantly improve wear resistance in industrial applications. Their unique structure minimises material degradation, reducing downtime and enhancing productivity.

These parts excel in high-stress environments, maintaining performance under demanding conditions. By integrating powdered metal components, industrial machines achieve greater reliability and cost-effectiveness.

Innovations in Powder Metallurgy Parts for Wear-Resistant Machinery

Recent advancements in material composition have further enhanced the durability of powder metallurgy parts. Innovations such as alloy optimisation and sintering techniques ensure superior performance in extreme conditions.

Manufacturing processes now incorporate precision engineering to create components with consistent quality. This ensures that powder metallurgy parts meet the rigorous demands of modern industrial machinery.

Fluid level sensors and switches can be integrated into hydraulic systems to monitor oil conditions. Monitoring oil temperatures and key component temperatures helps maintain optimal performance, extending the life of hydraulic systems.

Industrial Applications: Where Powdered Metal Parts Excel

Powdered metallurgy parts are widely used across industries requiring high durability and precision. Their wear-resistant properties make them indispensable in the following sectors:

• Automotive: Engine components such as gears and bearings benefit from reduced friction and extended service life, ensuring smoother operation and lower maintenance costs.

• Heavy Machinery: Excavators and loaders rely on powder metallurgy parts for enhanced durability under heavy loads, reducing wear and tear in demanding environments.

• Aerospace: Critical components in aircraft engines require the precision and reliability of metal powder components to withstand extreme temperatures and stresses.

• Agriculture: Machinery such as harvesters and tractors utilise these parts to withstand harsh environmental conditions, ensuring consistent performance in the field.

• Energy: Turbines and generators depend on powdered metal components for efficient and long-lasting performance, minimising downtime and operational disruptions.

• Manufacturing: Industrial presses and conveyors benefit from the wear resistance of these parts, maintaining productivity and reducing replacement frequency.

• Construction: Equipment like cranes and bulldozers uses powder metallurgy parts to ensure reliability in demanding projects, enhancing safety and efficiency.

Partnering with PM Distributors for Superior Solutions

Powdered metal parts from PM Distributors deliver unmatched precision and durability, ensuring industrial machinery operates at peak efficiency. Our expertise in advanced powder metallurgy techniques guarantees components that meet the highest standards of quality and performance.

Explore our range of metal powder components designed to meet your specific industrial requirements.

Read this blog for more information about the excellence of powdered metal parts: Reap the Benefits of Modern-Day Powder Metallurgy

Optimized by: Netwizard SEO