Blog

Why Sintered Glacier Bearings are Essential for Industrial Equipment

June 12, 2024

Discover why sintered Glacier bearings are essential for industrial equipment. Learn about the benefits of powder metallurgy over metal injection moulding.

When it comes to critical components like bearings, choosing the right material and manufacturing process can make all the difference in ensuring your equipment operates smoothly and efficiently.

At PM Distributors, we specialise in sintered Glacier bearings, a unique solution that combines the benefits of powder metallurgy with the superior performance of Glacier bearings.

The Advantages of Powder Metallurgy

Powder metallurgy is a manufacturing process that involves compacting metal powders into a desired shape and then sintering them at high temperatures to create a solid part. This process offers several advantages over traditional metal injection moulding, particularly when it comes to the production of bearings. Some of the key benefits of powder metallurgy include:

• Improved dimensional accuracy and tighter tolerances

• Reduced material waste and lower production costs

• Ability to create complex shapes and intricate designs

• Excellent mechanical properties, including high strength and wear resistance

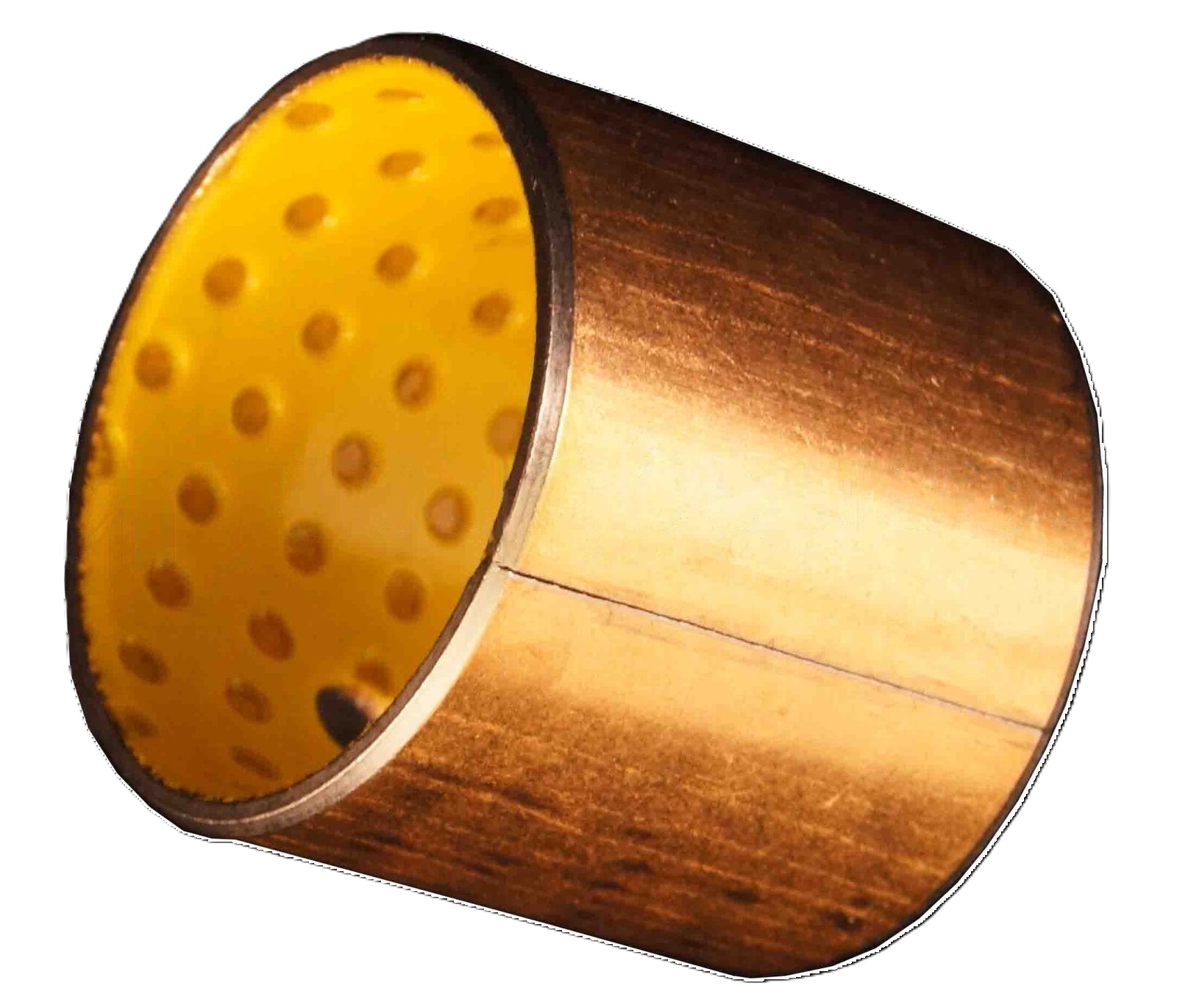

• Consistent microstructure and material properties throughout the part Glacier bearings are a unique type of bearing that combines the benefits of powder metallurgy with the superior performance of Glacier’s proprietary material formulation. Unlike traditional metal bearings, Glacier bearings are made from a sintered metal composite that includes a blend of copper, tin, and other alloying elements. This unique material composition offers several advantages over traditional bearing materials, including: • Excellent wear resistance and extended service life • Superior corrosion resistance, even in harsh environments • Ability to operate at high speeds and under heavy loads • Low coefficient of friction for smooth, quiet operation • Self-lubricating properties that reduce the need for external lubrication When it comes to industrial equipment, reliability and performance are critical. Downtime can be costly, both in terms of lost productivity and potential damage to equipment. That’s why sintered Glacier bearings are essential for a wide range of industrial applications, including: • Mining and construction equipment • Agricultural machinery • Material handling systems • Pumps and compressors • Automotive and aerospace components By combining the benefits of powder metallurgy with the superior performance of Glacier bearings, sintered Glacier bearings offer a unique solution that can help extend the life of industrial equipment and reduce maintenance costs. At PM Distributors, we are committed to providing our customers with the highest quality sintered Glacier bearings available. Our state-of-the-art manufacturing facility uses the latest powder metallurgy techniques to ensure consistent quality and performance, while our team of experienced engineers works closely with customers to develop customised solutions that meet their specific needs. If you’re looking for a reliable, high-performance bearing solution for your industrial equipment, sintered Glacier bearings are the smart choice. By combining the benefits of powder metallurgy with the superior performance of Glacier bearings, these unique components offer unparalleled reliability and durability in even the most demanding applications. Optimized by: Netwizard SEO

Why Sintered Glacier Bearings are Essential for Industrial Equipment

Our Commitment to Quality